The Diamond Manufacturing Process

Each and every diamond is sorted, analyzed and planned separately and requires the knowledge and experience of several experts in their fields. Once the diamond is planned and it’s “Yield” is estimated, everyone in the production line has the task of achieving the “target”. Diamonds are analyzed before, during and after each step of the manufacturing process.

Step #1) Assortment and Planning of the "Rough Diamonds"

This is of course the “initial stage” of the diamond manufacturing process. In this process, an expert analyzes the rough diamond to determine it’s characteristics.

The unique characteristics of each diamond are analyzed for the 4 C’s. (Cut,Carat,Clarity,Color) This will give a preliminary estimate, of the overall quality of the “rough diamond”

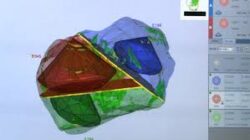

Step #2) Rough Diamond "Planning" and "Marking"

Planning is crucial to diamond manufacturing. Like any other work of art or architecture, a diamond is created twice. Once as a “blueprint” and again as the actual product.

There are various sub-processes in planning, such as (Marking, windowing & simulation)

Hi-Tech computer aided, 3 dimensional “simulation” systems are used to plan the diamond. The exact shape, size and purity of the diamond is determined at this stage. If the planning is not done efficiently, then significant value can be lost. The entire planning process is designed to “maximize” the value and beauty of each diamond and their soon to be diamond shape.

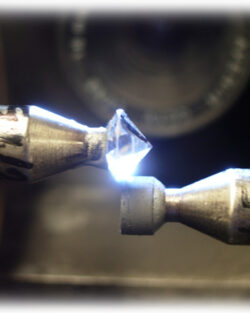

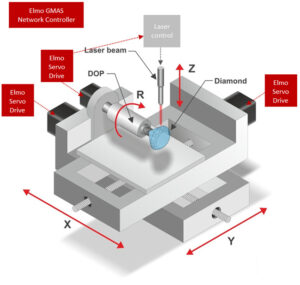

Step #3) Cleaving And Sawing

“Cleaving” and “Sawing are two different processes. Cleaving is essentially breaking up the rough diamond into parts. Sawing can also be used to perform this task, depending upon the need and desired results.

Lasers are the latest and most advanced technology being used by diamond manufacturers to saw diamonds. This method produces extremely accurate results.

“BLOCKING” is a process where the first eight facets are given to the diamond. This technique is used to reduce weight loss from cutting and polishing

“Auto-Blocking” is also used to perform faceting but is completely automatic. When one facet is polished, it automatically rotates and the second facet is started.

Step #4) Bruting

Bruting is essentially the process of giving the diamond “Shape” The “Bruter” considers such things as “maximum” yield, the symmetry of the diamond, and durability (making sure the diamond won’t break easy), utilizing advanced equipment.

Final Step #5) Polishing

Diamond Polishing Is the final step in the diamond manufacturing process. The “Bruted” diamonds are sent to the polishing phase. Again the diamond is analyzed. The “polisher” has to be very careful in this phase. Even a SMALL mistake can reduce the quality of the diamond. All facets of the diamond are polished.